3D Laser scanning services & As-Buit Surveys

We rebuild the geometry of elements and infrastructures using 3D laser scanner technology

Laser scanning and modeling services

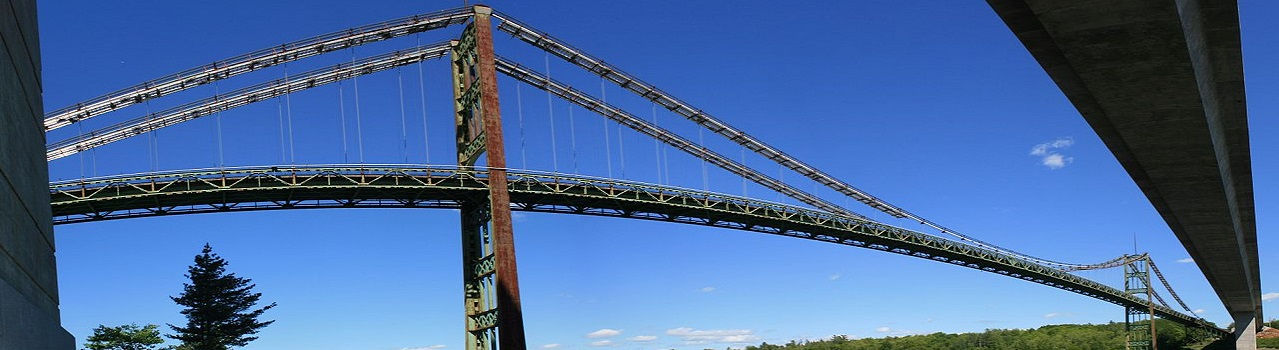

Our work relies heavily on the cutting-edge technologies of laser scanning and 3D scanning, often referred to as LIDAR (Laser Imaging Detection and Ranging). This advanced approach empowers us to amass a substantial volume of geometric documentation by meticulously collecting data and employing sophisticated 3D point cloud processing and editing software. Through this process, we can meticulously process the captured data, refining and organizing it into a comprehensive 3D point cloud.

Subsequently, this 3D point cloud serves as a foundational resource from which we craft highly accurate Building Information Modeling (BIM) models. The BIM models are constructed with a keen eye on precision and detail, all made possible by leveraging some of the most widely adopted design tools available in today's market, including Graphisoft Archicad, Autodesk Revit, Navisworks, and Autocad. These tools facilitate an efficient and effective translation of the intricate 3D point cloud data into precise BIM models, providing a robust representation of the physical structures or spaces.

In comparison to traditional methods, our approach stands as an outstanding alternative. Traditional techniques often grapple with challenges related to object accessibility, posing limitations on accurate measurements. Additionally, they struggle to ensure safety during measurements, and their processes can be time-consuming and less precise. Our modern approach utilizing laser scanning and 3D scanner technology significantly alleviates these limitations, paving the way for a more efficient, accurate, and safe methodology in the field of geometric documentation and BIM modeling.

3D Scanning Services

We perform accurate and detailed 3D scans of open spaces, large infrastructures, buildings, environments and objects, useful for the execution of projects in industry, architecture, heritage and many other areas.

In the measurement and planning phase of buildings, renovations, interiors and outdoor installations, detailed and reliable measurement data are especially necessary. Since accuracy and accurate measurements are the basis of any solid planning and documentation, the processing of simple 2D representations is no longer sufficient for the architecture and engineering sector today.

3D Point Cloud Generation

The point cloud is the result of the process of scanning the surfaces of the object, environment or infrastructure to be processed with the 3D terrestrial scanner and is constituted by the set of vertices in a three-dimensional coordinate system. These vertices are usually identified as X, Y, and Z coordinates and are representations of the outer surface of an object.

The great advantage of the point cloud is the possibility of using it in the most common software such as Autocad, Autodesk Revit, Graphisoft Archicad, Navisworks and other software on the market from the generated files.

Industrial facilities and MEP

Industrial and manufacturing facilities are highly dynamic spaces, so your 3D laser scanning solutions must also be dynamic.

Our job is to use our laser scanning solutions to create a 3D reality capture in a cloud of installation points and their content. Once the point cloud model is transferred to our client, they can integrate it into a modeling solution (eg Autodesk Factory Design Suite, Solidworks, Tekla, etc.) and use it as a basis to help locate equipment and create new flows of more efficient products. By creating a real shot, we can help our clients accurately calculate 3D space gaps and constraints.

Naval industry

The use of laser scanning in shipbuilding is a technology that helps shipyards deliver projects faster, more efficiently and with less risk. We are a company that specializes in quickly and accurately capturing current conditions, using the latest proven technologies in laser scanning and precision elevation, to achieve best practices for boat repair and new construction.

Scanphase collaborates with naval companies and field specialists and offers high quality services for shipping companies in all Spanish ports (Valencia, Algeciras, Barcelona, Las Palmas, Bilbao, Santander ...), Europe and North Africa.

The key to competitive use lies in being able to capture the boat

BIM models from point clouds

In Scanphase we produce complete and information-rich 3D BIM models from point cloud data. Our BIM Scan services are used due to our long-term experience of working on point cloud modeling projects. We have a team of architects, engineers and modelers from Scan to BIM with experience in the work of complex renovation projects. We have worked on the renovation and restoration of heritage buildings, government buildings, old commercial properties, residential apartments that must be demolished or updated with newer designs. Scan to BIM modeling services are extremely useful for achieving excellent renovation results in less time and cost compared to traditional methods.

Revit, Archicad, Naviswork models

The point cloud model is widely recognized as more accurate than traditional measurement methods.

3D laser scanning technology first captures the environment as it is built, then we import the data and process it using software such as Autodesk Revit ArchiCAD, Navisworks and others; This process is called point cloud conversion to 3D model. Our BIM experts can accurately transform point cloud data into a virtual model that is useful for architectural and engineering studies.

While BIM's main focus is on new building projects, the growing market for renovation and restoration projects has led to rapid growth in CAD scanning and BIM scanning services.

Geo-referencing point clouds

Reverse engineering services

Point clouds are increasingly becoming a common element in workflows for the generation of 3D models, particularly useful for BIM (Building Information Modeling) projects. One of the most important tasks for those who want to use a point cloud in a model with real coordinates is the geographical reference.

One of the biggest concerns when dealing with point clouds is the need to georeference them (transformation from Ground Control Points), or contextualize them within a coordinate system.

The geographic references of the data of the cloud of points is possible to insert them in multiple platforms, like Faro Scene, AutoCAD, Navisworks, Revit, Civil 3D and others.

Reverse engineering is necessary and is becoming increasingly popular as a method to create a 3D model of a CAD part. Reverse engineering rebuilds classic designs and implements new designs. You can generate lost or missing documentation of designs and update or create documentation according to the work.

With non-contact 3D laser scanning, portable image capture equipment integrates 3D modeling processes in one step. They can offer virtual simulations of interiors, speed up prototyping and inspect surfaces in assemblies. The applications are unlimited.

Orthoimages and 3D sections

We generate corrected views from the point cloud, in which all elements have the same scale, free of errors and deformations, with the same validity as a classical plane. These orthoimages combine the detail characteristics of a photograph with the geometrical properties of a plane and it is possible to realize them of different elements like main elevations of buildings, plants, cross-sections and longitudinals, vaults, etc. Showing them as 3D sections.

By having all the information in the files generated, it is possible to draw the sections by the most appropriate place. If you require more sections you do not need to re-capture data in the field.

Photographs and images 360

360 photography, spherical photography, panoramic image or 3D model generated on the basis of photographs is a photographic technique with which a series of photos is obtained of an object or space rotated or rotated in a complete circle, occasionally on multiple axes. Increasing the number of photos will improve the smoothing of transitions and is widely used in VR (Virtual Reality) applications.

Currently, our 3D laser scanning equipment allows, in addition to laser light measurements, to create 360 photographs by capturing photos of the scan area. With the great advantage of being able to georeference the images with the generated point cloud.

Other services

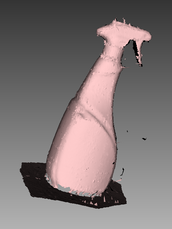

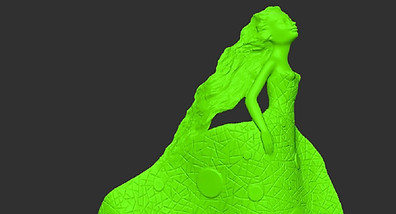

In our practice, we specialize in the digitization of diverse elements encompassing architecture, cultural artifacts, heritage items, and industrial components. Our goal is to replicate these entities with an exceptional degree of accuracy and precision across various scales. This intricate digitization process involves meticulous attention to detail, preserving the authentic dimensions and characteristics of the original object.

The process of digitization is comprehensive, capturing the essence of each part of the object meticulously. By carefully considering the specific dimensions and features of the object, we undertake the digitization in parts. This involves generating a detailed point cloud through an assemblage of approximately 4500 frames. These frames are pivotal in creating a comprehensive mesh of the final surface, forming the foundation for achieving realistic 3D printing in polymer materials.

The significance of our work extends beyond the technical aspects of digitization. It underscores the critical importance of 3D digitization, particularly in the realms of art, culture, and heritage. By enabling the accurate replication of items of significant historical, cultural, or artistic value, we empower wider accessibility and understanding. This digital representation grants the public access to a wealth of knowledge and facilitates virtual contact with high-value works that were previously only accessible through physical presence.

In essence, our approach to 3D digitization not only showcases technological advancements but also emphasizes the democratization of cultural heritage and the preservation of our rich history and artistic legacy for generations to come.

Reverse engineering of mechanical parts using 3D technology

Laser scanner and 3D scanner technology is an indispensable tool for sectors such as industrial metrology, the possibility of obtaining a virtual model completely faithful to the original in high resolution opens a huge field of possibilities for different disciplines. Once the digital model is obtained it is possible to reproduce it in different materials through CNC milling, 3D printing or to make design modifications. We perform the digitization of industry elements reproducing them with accuracy and precision at various scales, by means of the reverse engineering procedure to obtain information or a design from a product, in order to determine what is made, what makes it work and how it was manufactured.

For the capture of the information we use 3D laser scanners, obtaining information that after being processed can be delivered as parametric files ready to be used in CNC.

Polygon meshes

The polygon mesh is a representation of a 3D model made from thousands of points that are linked together by lines, which in turn form small polygonal shapes. The union of all these geometric elements results in a structure similar to a mesh that represents the surface of an object.

The components of a polygonal mesh simply represent the 3D shape of an object, which allows the use of the model in all computer graphics and 3D design applications and CAD software on the market for analysis and measurement. Additionally they are of great utility for the creation of models through the machining with CNC or 3D printers.

3D Virtual tours

Our process involves the creation of interactive videos depicting both interiors and exteriors, enabling real-scale virtual walkthroughs of scanned spaces. To achieve this, we utilize highly precise graphical representations of the scanned surfaces, enhancing the level of detail by incorporating the x, y, z coordinates of the points constituting the real surface. This approach encompasses accurate rendering of colors and textures, further augmenting the realism and fidelity of the generated content.

The fundamental technique involves transforming a dense point cloud derived from the scan data into a dynamic video format.