3D Laser scanning represents a significant advancement in the yacht building industry, revolutionizing processes and enhancing outcomes for various stakeholders. From initial planning through construction to interior furnishing, laser scanning stands as a reliable solution when precision is paramount.

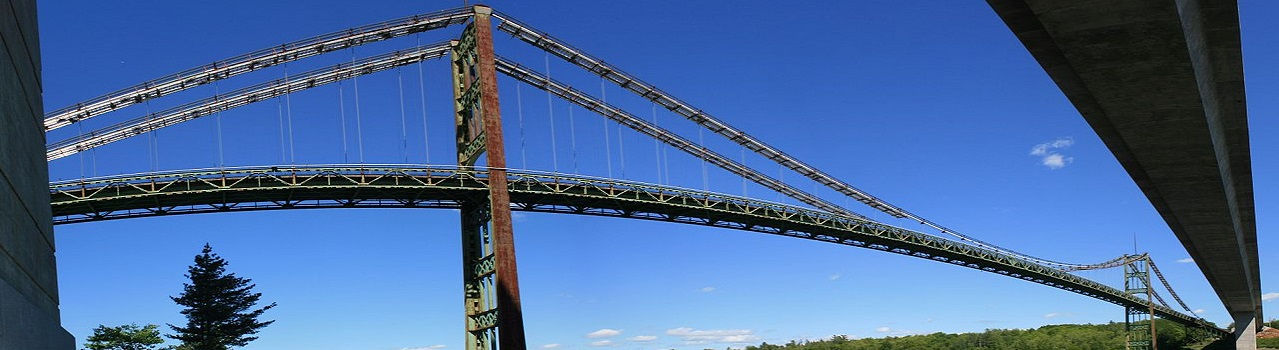

Scanphase collaborates closely with naval companies and field specialists, offering top-tier services to shipping companies across numerous European ports (Portugal, France, Italy, Spain, Malta, Netherlands, Germany, Belgium, Turkey, Gibraltar, Malta ...) and Spanish ports (Valencia, Algeciras, Barcelona, Las Palmas, Bilbao, Santander, Tarragona, El Ferrol, Cartagena, Aviles, Malaga, Mahon, Ibiza ...), extending its reach to North Africa.

3D Laser scanning is profoundly transforming the yacht building industry, enhancing both quality and efficiency across a spectrum of stakeholders. Whether in the stages of planning, construction, or furnishing, laser scanning offers a dependable solution when precision is paramount.

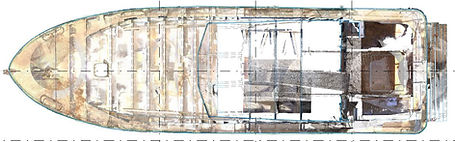

Ships, due to their nature, present a challenge for transportation to scanning sites, often incurring significant costs. Our 3D engineers overcome this challenge by setting up equipment on-site, adeptly moving between various ship areas, and seamlessly integrating scans to construct highly accurate 3D interior layouts. When combined with existing external ship designs, this approach results in a cohesive and comprehensive representation. The inclusion of colorized 3D point cloud scans and panoramic images provides perspectives on yacht data that were previously unattainable. It's crucial to note that a 3D scan serves as the initial phase of the Computer-Aided Design (CAD) journey.

The paramount advantage of employing 3D laser scanning for yachts prior to a refit lies in the precise data it provides during the redesign phase. This ensures that all design components will seamlessly translate into the production phase. Moreover, it allows for decentralized work allocation, avoiding the limitations of on-site work with confined space and resources. The applications of 3D laser scanning span a wide range, encompassing steelworks, railings, machinery spaces, interior areas, furniture, ceiling panels, windscreens, and virtually any yacht component.

Yacht 3D Laser scanning for retrofit - Point Cloud

In the yacht building industry, the utilization of a 3D laser scanner is distinctive and invaluable. Detailed ship design is paramount, particularly for creating comprehensive interior 3D drawings. Our 3D laser scanner excels in mapping out the ship with millimeter precision, providing an optimal foundation for crafting intricate interior designs.

Yacht laser scanning for fast and accurate retrofit

3D Yacht Laser scanning all surfaces

3D Laser scanning is a highly specialized task demanding meticulous setup to achieve precise and accurate results. Our equipment is portable, enabling scans to be conducted at the boat's location. However, a significant portion of the work occurs in the office post-scan. Post-processing is a crucial step in obtaining a highly accurate image and necessitates the expertise of a professional.

Scanphase utilizes long-range Faro Focus scanners, capable of achieving remarkable accuracy down to 1mm from distances of up to 330m. The Faro Focus scanner impressively measures nearly a million points every second.

When a boat is undergoing maintenance out of the water, it is not generating revenue. This underscores the importance of a swift turnaround. In scenarios where hull measurements are required for providing drawings to a naval architect, 3D laser scanning can efficiently and promptly accomplish the task, minimizing additional downtime.

3D Laser scanning yacht for retrofit

Yacht 3D Laser scanning and modelling

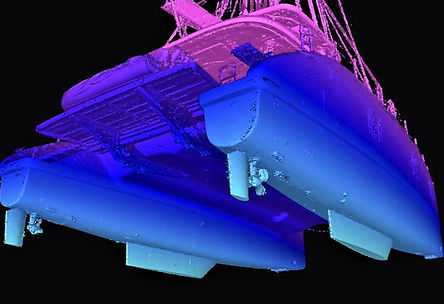

3D Laser Scanning / Hull scanning

Scanphase (3D laser scanning / CAD modeling) capture and deliver, very quickly, the complex geometries and shapes of boat hulls.

Specifically, 3D Laser Scanning can be performed for the definition of possible deflections of the hull as also to inspect every stage of the erection process for deviations from the design. Also, 3D Laser Scanner can survey complex surfaces as also unapproachable and destroyed areas for claiming and redesign. The great point sampling with 1.000.000 points per second can ensure the detailed and quick stay on the field. Any type of ship, from a sailing boat to a tanker and bulk carrier, in any place and in any time, can be surveyed.

The final unified and dense point cloud is the proper initial spatial information for the extraction of any kind of deliverables from naval lines (waterlines, buttocks and sections) to a 3D reconstructed ship geometry (modeling) in any compatible CAD format.

Scanning ship hull for major modification:

-

Capturing of complex and detailed surfaces.

-

Extraction of all possible geometrical information (dimensions, angles).

-

Faster repair times.

-

As built compatible data for CAD softwares for any naval designing department - office.

-

Accuracy with the true ship geometries.

-

Direct comparison with design plans.

-

Minimization of construction delays

3D Laser scanning yacht hull for retrofit

3D laser scanning applications in the realm of yacht boats

-

Complex Surface Capturing: 3D scanning swiftly and accurately captures the intricate surfaces and measurements of boats. Traditional methods would take weeks to achieve similar precision. This reliable data significantly simplifies boat refits and repairs.

-

Precise Measurements for Bespoke Parts: Utilizing 3D scans for refits and repairs allows for precise measurements of the existing space. When ordering bespoke parts and fittings, you can ensure they will fit perfectly the first time.

-

Simulating Design Performance: Scanning the hull of a yacht enables designers to simulate the design's performance in water, providing crucial insights for racing yacht designers.

-

Blueprints for Old Boats: Many old boats lack accurate drawings, essential for refits, repairs, and insurance. A 3D scan provides a detailed blueprint of the boat's actual condition, aiding in necessary modifications.

-

Preserving Historical Vessels: 3D scans are invaluable for recording data on historic vessels. This non-contact method allows historians to create precise blueprints, enabling the generation of 3D printed models for preservation and research.

Advantages of Yacht Laser Scanning: An Innovative Solution for the Nautical Industry

Yacht laser scanning represents a revolution in how luxury and high-end vessels are designed, maintained, repaired, and managed. Laser scanning technology, specifically adapted for yachts, offers multiple benefits that positively impact different stages of a vessel’s lifecycle. Below is a detailed description of these advantages, highlighting how this technological innovation brings precision, efficiency, and cost savings.

-

Extreme Precision and Detail: One of the main advantages of laser scanning is its ability to capture data with millimetric precision. Terrestrial or handheld laser scanners can obtain a highly accurate three-dimensional representation of all surfaces of the yacht, including complex curved areas, ornamental details, internal mechanical systems, and external structures. This accuracy allows for digital models that are extremely faithful to the physical reality, which is essential for tasks such as design modifications, repairs, or restorations. Moreover, laser scans eliminate human error commonly seen in traditional measurements, ensuring consistent and reliable data. This is particularly vital for yachts, where architectural and mechanical details must fit precisely to ensure structural integrity and aesthetics.

-

Speed and Efficiency in Data Capture: Another significant advantage is the speed at which complete data can be obtained. Unlike manual measurement methods, which can be labor-intensive and time-consuming, laser scanning collects all the necessary information within hours—or even minutes—depending on the size and complexity of the yacht. Faster data collection means design, maintenance, or repair processes can begin sooner, reducing project timelines and expediting delivery. In a sector where time is money, this efficiency can be the difference between an on-time repair and a costly delay.

-

Detailed Documentation and Full Digitalization: Laser scanning produces 3D digital models that serve as exhaustive documentation of the yacht’s current state. This full digitalization is invaluable for multiple applications: a. Predictive and Preventive Maintenance: Up-to-date digital models help detect wear, deformations, or structural damage before they escalate. b. Repairs and Restorations: The digital model allows precise planning of interventions, ensuring new or modified parts fit perfectly. c. Reproduction and Manufacturing: Enables the creation of custom parts via 3D printing or CNC machining with guaranteed fit and precision. d. Historical Records: Maintaining accurate digital records helps with long-term vessel management, preserving both the original state and any modifications over time.

-

Enhanced Design and Customization: Laser scanning enables naval designers and architects to produce digital models that accurately reflect the yacht's existing dimensions. This means modifications, expansions, or customizations can be planned with greater precision, reducing errors and the need for rework. For instance, if a client wants to add a cabin, install advanced sound systems, or alter the interior layout, laser scanning provides the data needed to design these changes efficiently. It also enables 3D visualizations that help clients understand the outcome before any physical work begins.

-

Cost Reduction and Risk Minimization: Although the initial investment in laser scanning technology may seem high, the long-term cost savings are substantial. Accurate measurement and documentation prevent errors that could result in additional repairs or costly adjustments. Laser scanning also minimizes risks associated with inaccurate measurements, which could compromise a yacht’s structural integrity or final appearance. Accelerated design and repair processes shorten vessel downtime, reducing economic losses caused by immobilization.

-

Maintenance and Repair Facilitation: Access to precise 3D models greatly aids in maintenance and repair tasks. Technicians and experts can use this data to plan targeted interventions, quickly locate problematic or hard-to-reach areas, and perform repairs with greater accuracy. For example, in the case of internal system damage or hull structure issues, laser scanning can detect hidden deformations or wear—even in areas not visible to the naked eye. This improves work quality and extends the yacht’s lifespan.

-

Inventory and Spare Part Management Optimization: Thanks to the digital models generated by laser scanning, companies and yacht owners can manage their inventory of spare parts and components more effectively. Precise digitalization supports the creation of detailed catalogs, simplifies ordering processes, and ensures manufactured parts are identical to the originals, reducing errors and returns.

-

Support in Construction and Manufacturing Processes: For new builds or extensions, laser scanning can verify manufacturing accuracy against original blueprints. This ensures proper fit and construction quality. It also facilitates the integration of new components with existing structures, guaranteeing compatibility and a perfect fit.

-

Compliance and Regulatory Documentation: Laser scanning also supports compliance with international regulations and legal requirements related to safety, structure, and vessel certification. Having accurate, up-to-date digital models can serve as evidence during audits, inspections, and certification processes.

-

Sustainability and Environmental Impact: Last but not least, laser scanning technology fosters a more sustainable approach to yacht management. By reducing the need for physical travel, repeated measurements, and error-induced waste, it lowers the environmental impact associated with maintenance and repair operations